Behind the Scenes with ICC Brazil: learn about the processing of yeast-based products

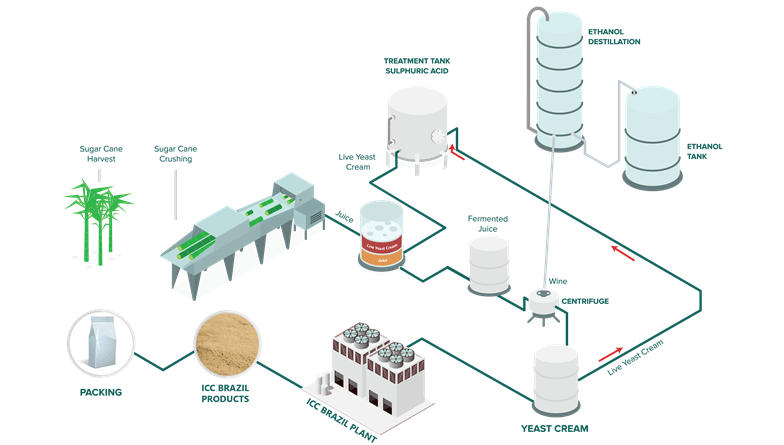

Learn more about how the process of obtaining ethanol from sugarcane transforms it into efficient solutions for animal health and nutrition.

Many people want to know how ICC Brazil’s solutions are originated from the processing of sugarcane. This process, which involves several stages and many contributors, is explained to you by the Chemical Engineer Bruno Fantini Paludetto, Production Coordinator at ICC Brazil. Join us as we show you how it all works!

It all starts with the Sales team ordering the products needed from ICC Brazil’s Supply team, and then, the raw materials for production are selected. The yeasts used as raw material come from sugar and alcohol production plants. Those used by ICC Brazil are specifically derived from the processing of sugarcane fermentation to obtain ethanol.

The yeast cream used in the process undergoes alcoholic fermentation several times, providing yeasts with unique characteristics such as the greater density of their cell wall. From this point on, we have different processes that result in several of the products in the ICC Brazil’s portfolio. The dry and inactive yeasts undergo a drying process and do not suffer rupture of the cell wall, being a great source of B vitamins, proteins, and glutamic acid.

There are also autolyzed yeasts that, through the rupture of the cell wall, make their rich intracellular content available. Then, the hydrolyzed ones that, after the rupture of the wall, can offer free nucleotides and nucleosides through specific enzymes. Finally, we have the yeast cell walls, with high concentrations of β-glucans and MOS.

It is worth mentioning that ICC Brazil products’ quality is what stands them out in the crowd. This is because the entire team is continually committed to delivery, and all products are tested at different stages of the process always to ensure the best quality and composition.

ICC Brazil works daily seeking innovation, being guided by market research, where the needs of producers are identified. From then on, tests are carried out in laboratories to determine the initial effectiveness of the active ingredient that will originate the product according to each objective.

After this stage, field tests are developed to prove the product’s in vivo efficacy, and, if they are proven effective, the dosages to provide the best responses are defined. Finally, the cost-benefit ratio of the product is evaluated, seeking to measure the final cost for the producer, its profitability, and its viability in the market.

Learn more about the ICC Brazil’s teamwork

For all this to happen, ICC Brazil has a whole team committed to the end quality. Everyone involved is trained to follow all food and product safety standards. The people in charge of each area are always in touch with all shifts, guiding and training them so that the delivery of high-quality solutions to customers is maintained.

Recently, ICC Brazil had significant growth in the production of the plant. Therefore, the team was challenged to meet the challenges and continue to work with great effort and dedication to serve all customers and further increase their productive capacity.

Now that you know the details behind the scenes of ICC Brazil’s production, it’s time to get to know all our products better. Access the website and find out how efficient yeast-based solutions contribute to the development of the animal production chain: https://www.iccbrazil.com/linha-produtos/

Posted in 23 September of 2020